What do auto parts, bank cards, books, bottle labels, textiles, packaging and washing machines have in common? They all feature premium hot stamping and coating technologies, including security holograms, that are developed by Furth-based company Leonhard KURZ Stiftung & Co. KG. The global leader in the field has over 5,000 employees spread over six continents.

Investing in sustainability

Markus Hoffmann, Member of the Management Board and Senior Vice President of Leonhard KURZ Stiftung & Co. KG, is very clear that the hidden champion has set itself ambitious carbon saving targets: “In ten years’ time, we plan to have cut our emissions by 30 to 40 percent.” These ambitions require effort: “The investments we make in this cause are at our own risk. Reducing base thickness and recycling all cost money. Our investment strategy is focused on a long-term payoff.” But Kurz is already in the forefront where making material savings is concerned.

The thinnest coatings in the world

The layer thickness used in Kurz’ transfer coating processes is just 1.5–3 μm, the slimmest coating in the world. The finish is applied to plastic, paper and cardboard in wastewater-free dry processes such as hot stamping and cold and digital transfer. “As a result, our decorative finishes use 80 percent less carbon and can easily be recycled and deinked.” The aim is for all materials used in these complex processes to be separable and recyclable. Annie Kuschel, Head of Design Management, explains how it works: “Paper and card decorated with our transfer coatings can be processed by all the commonest types of collection, sorting and recycling equipment.”

Genuine circular economy

A critical part of the process involves returning all materials to where they were produced. “Processes have a future if we can use them to create a genuine circular economy,” says Markus Hoffmann, and Annie Kuschel describes the next steps along the way: “We have worked with partners in Germany and Europe to develop a qualified returns process, and are currently in the process of building a recycling plant.” At the plant, the base material will be taken back and recycled and reused for new products. Closed material cycles like this are the only way to create a genuine circular economy.

The future is digital

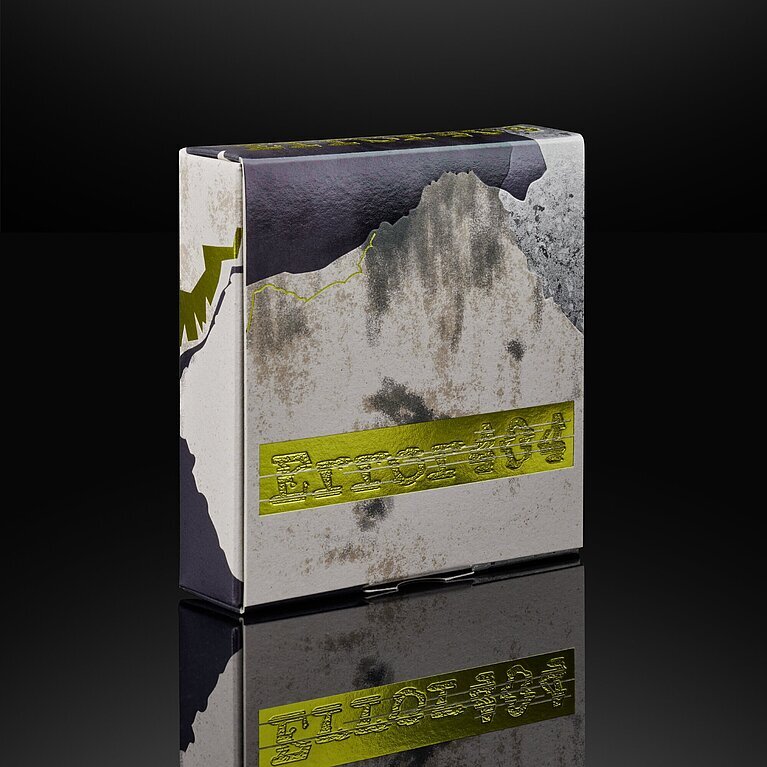

Although the company still bears the name of its founder Leonhard Kurz, who launched his specialist gold leaf production in 1899, it has long since diversified and now supplies holograms and security elements for banknotes and cards, finishes for tubes and cosmetics, metallic textile products, and much more besides.Computer technology is an indispensable aid to developing the perfect coating. The next step is “Dream Composer,” a software program for viewing decorative elements, effects and materials before printing. The software enables every aspect to be checked thoroughly, eliminating unnecessary production and waste. Also a sustainable approach. Nature has had millions of years to perfect its design. What can we learn from it?Sustainability “is often a matter of small steps,” says Markus Hoffmann. It’s all about taking the next step.

Strengthening designers

Sound like a tech company? It is. Drawing on its extensive design expertise, Leonhard KURZ Stiftung & Co. KG also partners with designers of auto interiors, consumer electronics and label, packaging and textile design. The company focuses its operations on creating unique products as sustainably as possible. The in-house team at Kurz conducts research on materials, coatings and effects and their impacts on the world of professional creativity. Annie Kuschel is already announcing the next stage: “sustainable packaging design, which we will debut at the Drupa trade show in Duesseldorf (May 28–June 7).”